Have you ever wondered how to achieve efficient grinding for various sample types? What are the challenges that researchers face when grinding diverse samples? And how does the Mortar Grinder address these challenges?

Grinding diverse samples presents unique obstacles, from hard and brittle materials to irregular shapes. How can the Mortar Grinder overcome these challenges? With its versatile design and capabilities, the Mortar Grinder is purposefully engineered to handle various sample types and sizes, making it an indispensable tool for efficient grinding processes.

Efficiency is the key to unlocking the true potential of sample preparation. This instrument is a cutting-edge solution that delivers efficient grinding performance across various sample types.

Understanding the Challenges of Grinding Diverse Samples

Grinding diverse samples is not a one-size-fits-all task. It requires a deep understanding of the unique challenges that different sample types present. One key aspect we explore is the variability in sample hardness.

Some samples may be extremely hard, requiring specialized grinding techniques to break down their structure effectively. On the other hand, some samples are softer and more delicate, which need to be handled with care to avoid excessive damage during grinding. By understanding the hardness spectrum and tailoring grinding approaches accordingly, the RnD team in the company can optimize their processes for each sample’s specific needs.

Another challenge lies in the brittleness of certain samples. Brittle materials tend to fracture easily, making it challenging to achieve uniform grinding. We delve into strategies for overcoming this obstacle, including using appropriate grinding media and adjusting grinding parameters to minimize sample fragmentation and maximize grinding efficiency.

What is The Mortar Grinder?

The mortar grinder is a remarkable tool specifically designed to meet the diverse needs of grinding, homogenizing, and mixing samples under various conditions, including dry, wet, or cryogenic environments. With its exceptional performance and user-friendly operation, this versatile ball mills instrument has become indispensable in scientific research and laboratory workflows.

One of the mortar grinder’s key strengths is handling various sample types. This grinding device can effectively process various materials from soils, chemical products, medicinal herbs, yeast cells, and cocoa to food, grains, oils, fruits, salts, slag, silicate, glass, ceramics, and cement clinker. Whether the sample is hard, soft, brittle, or pasty, the mortar grinder delivers reliable and consistent results, ensuring homogeneity and uniformity.

Its exceptional processing capacity sets the mortar grinder apart, allowing researchers to handle large sample volumes efficiently. Its robust design and high-quality materials can withstand demanding grinding tasks while maintaining optimal performance. Additionally, the mortar grinder offers a user-friendly and safe operation, providing researchers with peace of mind during sample preparation. Its intuitive controls, ergonomic design, and safety features ensure smooth and hassle-free grinding processes, minimizing the risk of accidents or sample contamination.

The mortar grinder’s versatility, exceptional performance, and user-friendly operation make it an invaluable tool in scientific research across various disciplines. From chemistry, biology, and pharmaceutical research to materials science, geology, and forensic analysis, the mortar grinder excels in grinding, homogenizing, and mixing samples for further analysis. Its flexibility in accommodating different sample types and conditions, processing capacity, and safety features make it a go-to solution for efficient sample preparation.

The Working Principle of the Mortar Grinder

The Mortar Grinder, the oldest grinding principle, utilizes pressure and friction to achieve optimal results. The pestle applies pressure against the mortar’s walls and bottom, resulting in uniform and gentle grinding through friction. This method allows for mixing, homogenizing, and processing organic and inorganic samples without thermal stress. Operating at 50 to 130 rpm ensures consistent grinding, whether dry or in suspension.

The grinder’s scraper feeds the sample material between the mortar and pestle, facilitating continuous exposure and intensive mixing. Unlike conventional designs, the pestle is offset within the mortar, causing automatic rotation upon contact. The grinding pressure is achieved through the pestle’s weight and adjustable spring pressure on its axis.

Understanding the Mortar Grinder’s working principle enables efficient use. Its pressure and friction-based grinding, gentle mixing, and homogenization minimize thermal load and maximize results. This versatile instrument benefits various scientific disciplines, enhancing the laboratory’s grinding, mixing, and homogenization processes.

What is The Advantage of Mortar Grinder for Industries?

The Mortar Grinder offers several advantages and benefits for industries in various applications. Here are some advantages of using a Mortar Grinder in industrial settings.

1. Versatile Sample Preparation

The Mortar Grinder is capable of grinding, homogenizing, and mixing a wide range of samples, including hard, soft, brittle, and pasty materials. This versatility makes it suitable for industries with diverse sample types, such as pharmaceuticals, food processing, agriculture, chemicals, and more.

2. Efficient and High-Quality Grinding

The Mortar Grinder provides efficient and high-quality grinding results. It can achieve fine particle sizes and desired fineness, allowing precise control over the grinding process. This is crucial in industries where the particle size distribution and consistency of the samples are important for product quality, research, or analysis.

3. Sample Extraction and Homogenization

In addition to grinding, the Mortar Grinder can be used for sample extraction and homogenization. It helps release compounds from solid samples and facilitates uniform mixing, ensuring representative and consistent samples for further analysis or processing.

4. Multifunction Grinding

The Mortar Grinder offers the flexibility to perform grinding under dry, wet, or cryogenic conditions. Dry grinding is suitable for solid and brittle samples, while wet grinding allows for the addition of liquid to aid in the grinding process or prevent sample heating. Cryogenic grinding using liquid nitrogen is particularly useful for temperature-sensitive materials.

5. User-Friendly Operation

Mortar Grinders are designed with user-friendly features, making them easy to operate and control. They often come with intuitive controls, digital displays, and programmable settings, allowing operators to set and adjust parameters easily.

6. Reproducibility and Consistency

The Mortar Grinder enables reproducible and consistent results. Its controlled grinding process ensures that samples undergo consistent grinding and mixing, minimizing variations and ensuring reliable and repeatable outcomes. This is crucial in industries that require consistent sample preparation for quality control, research, or production.

7. Enhance With Safety Features

Mortar Grinders are equipped with safety features to ensure operator protection. These features may include safety interlock systems, overload protection, and ergonomic designs that minimize the risk of accidents or injuries during operation.

8. Time and Cost Savings

The Mortar Grinder can significantly reduce the time and cost of sample preparation. It offers a fast and efficient grinding process, allowing industries to process a large number of samples in a shorter amount of time. This can lead to increased productivity and cost savings in labor and resources.

These benefits make it a valuable instrument for industries that require reliable and high-quality sample preparation for various applications, ranging from research and development to quality control and production processes.

Application of Mortar Grinder: Versatile in Various Industries

The Mortar Grinder is not limited to a single industry or specific sample type. Its adaptability and exceptional grinding capabilities make it a sought-after instrument in various fields.

1. Pharmaceutical Industry

Mortar Grinders are widely used in the pharmaceutical industry for sample preparation during drug development, formulation, and quality control. They are employed for grinding and homogenizing various pharmaceutical materials, including active pharmaceutical ingredients (APIs), excipients, powders, tablets, and capsules.

2. Food and Beverage Industry

In the food and beverage industry, the Mortar Grinder aids in sample preparation for quality control, research, and development. It efficiently processes ingredients such as spices, cocoa, grains, and oils, ensuring consistent particle size and texture. This contributes to product uniformity and enhances flavor extraction, improving food and beverage formulations.

3. Chemical Industry

The chemical industry extensively uses Mortar Grinders for grinding and mixing chemical compounds, catalysts, pigments, polymers, and other materials. They are valuable tools for sample preparation in research, development, and quality control laboratories.

4. Material Science and Metallurgy

Mortar Grinders are employed in material science and metallurgy to prepare samples for analysis, testing, or research. They are utilized for grinding and homogenizing materials such as ceramics, minerals, alloys, ores, and powders.

5. Geology and Mining

Mortar Grinders find applications in geology and mining industries for preparing geological samples, rocks, minerals, ores, and pigments. They are used to obtain finely ground samples for analysis, mineral identification, and research purposes.

6. Academic and Research Institutions

Mortar Grinders are extensively used in academic and research institutions across various disciplines, including chemistry, biology, physics, and materials science. They are valuable tools for sample preparation, research, and experimentation.

7. Herbal Medicine and Natural Products

Mortar Grinders are commonly used in the herbal medicine and natural products industry for grinding and preparing herbal extracts, botanicals, roots, and plant materials. They assist in sample preparation for traditional medicine, phytochemical analysis, and formulation development.

8. Cosmetics and Personal Care

The cosmetics and personal care industry uses Mortar Grinders for grinding and blending cosmetic ingredients, pigments, powders, and formulations. They aid in sample preparation for product development, quality control, and stability testing.

9. Cement and Construction Materials

Moreover, the Mortar Grinder finds applications in the construction industry. It is utilized for grinding and homogenizing cement clinker, silicate, glass, and ceramics, ensuring the quality and performance of construction materials. By achieving uniform particle size and distribution, the Mortar Grinder assists in optimizing the properties of building materials, contributing to structural integrity and durability.

These industries demonstrate the wide-ranging applications of Mortar Grinders in various sectors. The versatility, precision, and efficiency of Mortar Grinders make them essential tools for sample preparation, research, quality control, and production in numerous industrial and scientific fields.

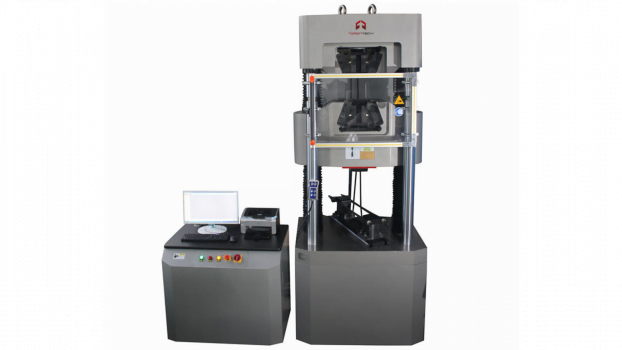

Key Features of Mortar Grinder MG200

With a focus on versatility and performance, the Mortar Grinder MG200 is engineered to deliver exceptional results in grinding, homogenizing, and mixing a wide range of samples. Whether operating in dry, wet, or cryogenic conditions, this powerful instrument is designed to meet the needs of various applications.

This instrument surpasses expectations with its ability to easily handle hard, soft, brittle, and even pasty samples. Its processing capacity is unmatched, allowing for efficient sample preparation. Moreover, the grinder’s user-friendly interface ensures a seamless operation, prioritizing user safety and convenience.

The Mortar Grinder MG200 offers a range of key features that make it a versatile and efficient tool for sample preparation.

1. Simple to Clean

The Mortar Grinder MG200 is designed for easy cleaning. After grinding, the mortar and pestle can be separated for thorough cleaning, ensuring the removal of any residue or cross-contamination between samples. This feature helps maintain sample integrity and prevents contamination in subsequent grinding sessions.

2. Convenient and Secure to Use

This instrument offers a user-friendly design with convenient features. It provides easy access to the grinding chamber, allowing for efficient loading and unloading of samples. The secure locking mechanism ensures that the mortar and pestle remain firmly in place during operation, preventing accidental spillage or disruption.

3. Expertise for Achieving Optimal Grinding Results

It offers precise control over grinding parameters such as grinding time, speed, and pressure, allowing users to tailor the grinding process to their specific needs. This expertise enables consistent and reproducible grinding outcomes.

4. Suitable for Dry, Wet, and Cryogenic Grinding

The MG200 is versatile and suitable for various grinding methods. It can perform dry grinding, wet grinding, and even cryogenic grinding. This flexibility allows users to adapt the Mortar Grinder to their specific sample requirements and optimize the grinding process accordingly.

5. Help to Prepare Rough Samples

Our Mortar Grinder is the answer if you need a tool to help prepare rough samples effectively. Whether grinding hard, brittle materials or samples with irregular shapes, the Mortar Grinder can handle the task. Its robust construction and powerful grinding mechanism make it suitable for processing challenging samples.

6. Adding Samples Through the Fill Opening While in Operation

The MG200 features a fill opening that allows samples to be added while the grinder operates. This feature enables continuous grinding without the need to interrupt the process of sample addition. It enhances workflow efficiency and saves time during sample preparation.

7. Multiple Scraper Materials Available

This instrument offers a range of scraper materials to meet different application needs. These include options such as polyurethane, PTFE (polytetrafluoroethylene), and beech wood. Scraper material choices allow users to select the most suitable option based on the sample type, desired fineness, and potential material compatibility requirements.

These key features of the Mortar Grinder MG200 contribute to its usability, versatility, and effectiveness in sample preparation. From its ease of cleaning and secure operation to the ability to handle various grinding methods and accommodate different sample types, the MG200 offers a comprehensive solution for achieving optimal grinding results in various applications.

Conclusion: Choice The Mortar Grinder MG200 for Efficient Grinding in Your Industries

In the quest for optimal sample preparation solutions, the Mortar Grinder MG200 emerges as the clear choice for industries seeking efficiency and precision in their grinding processes. With its user-friendly design, versatile capabilities, and robust performance, the MG200 offers a compelling solution to the challenges of grinding diverse sample types.

By selecting the Mortar Grinder MG200, you are equipping your laboratory with a cutting-edge instrument that streamlines the grinding process, enhances productivity, and ensures consistent results across various materials. From hard and brittle substances to irregular shapes, the MG200 is engineered to handle the toughest grinding challenges with ease and precision.

Investing in the Mortar Grinder MG200 is not merely a choice—it’s a commitment to excellence. Experience the transformative power of cutting-edge technology tailored to meet the demands of modern research and development.

If you have any questions or would like to learn more about the MG200 Mortar Grinder, we are here to assist you. Our team is dedicated to providing exceptional support and guidance, ensuring that you have the information and resources you need to make an informed decision.

Contact us today to discover how the MG200 Mortar Grinder and our extensive ranges of Ball Mills that can elevate your sample preparation processes and help you achieve unparalleled results.