Plastic Shredder for Comprehensive Plastic Waste Management

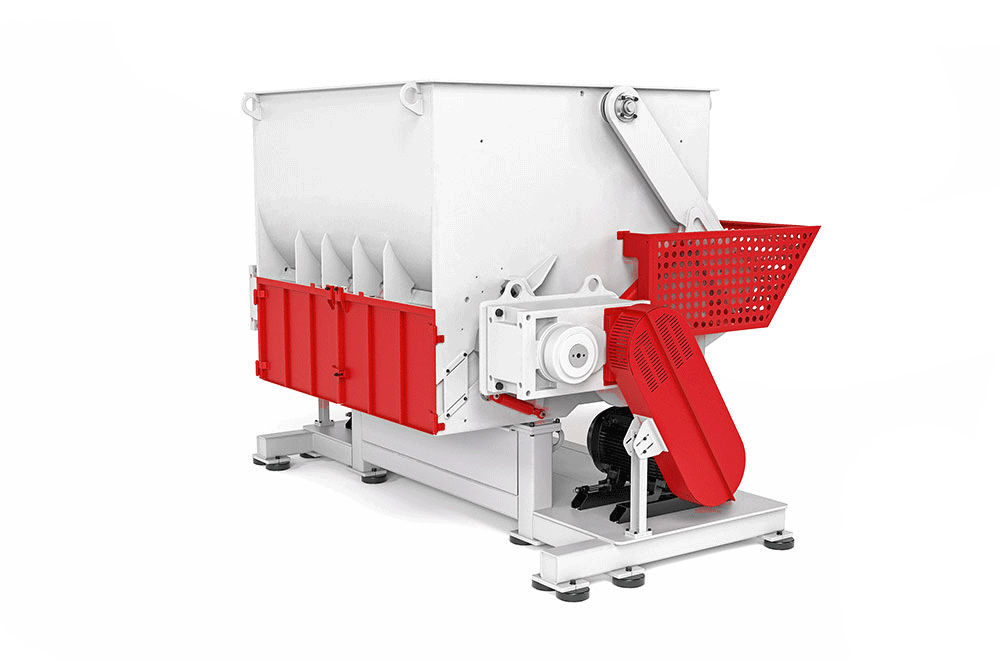

The plastic shredder is designed to handle various plastic materials, including PET bottles, pipes, and other plastic products. With its robust construction and powerful motor, this shredder machine efficiently reduces plastic waste into smaller, uniform pieces, making it easier to process recyclable plastic. Whether used in industrial recycling plants or smaller operations, this machine ensures fast and reliable shredding, maximizing throughput while minimizing energy consumption.

Ideal for handling shredding plastic, such as packaging waste, containers, and other bulky items, the machine's advanced features offer precision in operation and durability in tough environments. It is perfect for preparing materials for further recycling or repurposing, contributing to sustainable and cost-effective waste management solutions.

Product Categories

Shredder - Single Shaft Hard Plastic Shredder

The Shredder - Single Shaft Hard Plastic Shredder is a large single-shaft shredder known for its substantial internal volume...

Shredder - Carbon Steel Plastic Shredder

The Shredder - Carbon Steel Plastic Shredder is a large single-shaft shredder known for its substantial internal volume...

Shredder - Adjustable Pipe Waste Plastic Shredder

The Shredder - Adjustable Pipe Waste Plastic Shredder is specifically designed for recycling companies managing large volumes of waste plastic...

Shredder - Plastic Waste Single Shaft Shredder

The Shredder - Plastic Waste Single Shaft Shredder is specifically crafted for small-volume and thin-walled waste plastic products...

Shredder - Single Shaft Plastic Shredder For Pipe Recycling

The primary focus of the Shredder - Single Shaft Plastic Shredder For Pipe Recycling For Pipe Recycling is to shred large-diameter pipes or bundles of...

Shredder - Plastic Recycling Shredder Machine For Waste Management

The Shredder - Plastic Recycling Shredder Machine For Waste Management For Waste Management is known for its cost-effectiveness and versatility...